25-09-02

Dezhou Drillstar Cutting Tool Co., Ltd.: Decades of Craftsmanship Create an “Efficiency Engine” in Cutting

In the vast landscape of manufacturing, cutting tools, small tools, hold the key to production efficiency and product quality. A high-performance cutting tool can make a production line run as efficiently as a precision instrument; however, a poor-quality tool can lead to a chain reaction of scrapped workpieces, soaring rework rates, and production halts, becoming a significant obstacle to cost reduction and efficiency improvement.

Dezhou Drillstar Cutting Tool Co., Ltd. has been diligently cultivating the industrial cutting field for a decade, always committed to solving manufacturing pain points. Through continuous technological innovation, it has broken the industry’s predicament of “making do with just making do” tools and has become a trusted “efficiency engine” for numerous manufacturing companies. Selecting materials is like choosing a general, forging a “steel warrior.” In the world of cutting tools, materials are the foundation, determining a tool’s effectiveness.

Dezhou Drillstar Cutting Tool Co., Ltd. takes an unconventional approach, resolutely eschewing ordinary steel in favor of imported aerospace-grade carbide as its base material. This coating, like a “golden armor,” coats the cutting tools. This base material undergoes vacuum sintering at 1600°C and then cryogenic treatment at -196°C, a process reminiscent of a phoenix rising from the ashes, ultimately reaching a hardness exceeding HRC65 and a toughness 50% greater than that of conventional cutting tools. Whether it’s the tough challenges of cutting high-strength stainless steel, withstanding the indomitable resistance of wear-resistant cast iron, or machining specialized aerospace alloys, Drillstar’s tools maintain an intact cutting edge, preventing chipping and curling.

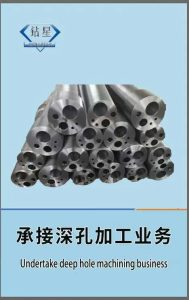

Tested data shows that their service life is over 40% longer than the industry average, allowing production lines to put an end to the hassle of frequent tool changes and return to efficient operation. Controlling micron precision and honing the cutting edge is the soul of cutting tools and the forte of Dezhou Drillstar Cutting Tool Co., Ltd. To achieve the ultimate in precision, Dezhou Drillstar Cutting Tool Co., Ltd. uses imported German five-axis grinding machines, coupled with a laser inspection system, to perform micron-level machining and calibration of cutting edges, a feat truly achieved with millimeter-level accuracy. The resulting cutting edge tolerance is strictly controlled to within 0.003mm, equivalent to 1/20th the diameter of a human hair—an astonishing level of accuracy! This “magic of precision” allows Drillstar tools to handle everything from milling complex surfaces to drilling deep holes with aspect ratios exceeding 10:1, ensuring that every workpiece’s dimensional tolerance is precisely controlled and within standard limits.

This not only reduces the time and cost of subsequent grinding and correction processes, but also maintains a product qualification rate of over 99.8%, safeguarding the company’s product quality. Adapting to all scenarios, customizing “exclusive cutting tools.” Different industries and processes have unique tooling requirements, like the stars in the sky. Automotive parts processing demands high speeds and continuous cutting; precision mold manufacturing requires complex cavities; and the aerospace industry places extremely high demands on tooling for high-temperature and fatigue resistance.

Dezhou Drillstar Cutting Tool Co., Ltd. understands this and has assembled a professional technical team to provide customized solutions for companies. From in-depth analysis of working conditions and meticulous tool parameter design upfront, to thoughtful user guidance and wear repair recommendations later on, the Drillstar team provides comprehensive support, ensuring every tool is perfectly matched to the production line, becoming the company’s “best partner.” Today, Drillstar Tools has expanded nationwide, serving over 1,000 manufacturing companies across a wide range of sectors, including automotive, aerospace, precision molds, and medical devices. Numerous customers report that using Drillstar tools has reduced tool changes by 35%, reduced workpiece rework by 28%, and increased overall production efficiency by nearly 30%. These tangible benefits have earned Drillstar Tools a strong reputation within the industry. Choosing the right cutting tool is a shortcut for manufacturers on the road to cost reduction and efficiency improvement.

Dezhou Drillstar Cutting Tool Co., Ltd., leveraging a decade of unwavering expertise, ensures precise and controllable cuts and maximizes every minute of production capacity. If your production line is still plagued by tooling issues, consider Drillstar Cutting Tool. Let our expertise supercharge your production efficiency and usher in a new chapter of efficient production!